If you’re in the market for a liquid filter bag, you may be wondering how it works and what benefits it provides. A liquid filter bag is a key component of many industrial processes that require the removal of impurities from liquids. In this article, we’ll take a closer look at the technology behind liquid filter bags and how they work to improve the quality of liquid filtration.

What is a Liquid Filter Bag?

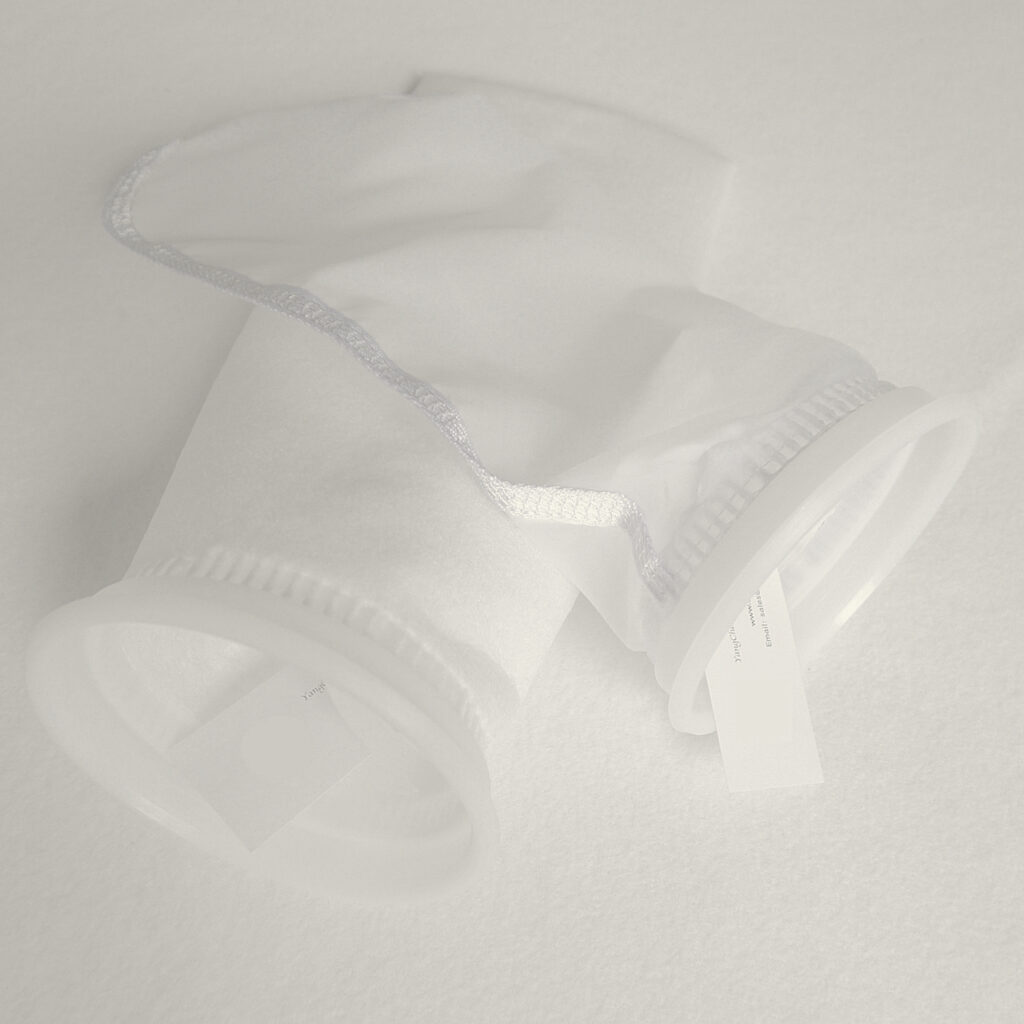

A liquid filter bag is a specially designed bag made from a range of materials, including felt, mesh, and membrane. The bag is placed inside a filter housing, and liquid is pumped through the bag, which captures any contaminants. The contaminants are then trapped inside the bag, while the filtered liquid passes through the bag and exits the housing.

How Does a Liquid Filter Bag Work?

Liquid filter bags work based on a simple principle: the liquid to be filtered flows through the filter bag, and the bag captures any impurities. The bags are typically made from synthetic materials, such as polyester or nylon, which have high tensile strength and chemical resistance.

When the liquid flows through the filter bag, any particles that are larger than the pore size of the bag are trapped inside. The size of the particles that can be filtered depends on the pore size of the bag, which can range from 1 micron to 300 microns for felts bag and 1 micron to 2000 microns for mesh bag. For example, a 1-micron filter bag can capture particles as small as 1 micron, while a 100-micron filter bag can capture particles as small as 100 microns.

The pore size of the filter bag is an essential factor to consider when selecting a liquid filter bag. The bag’s pore size should be selected based on the size of the particles you need to remove from the liquid. If the bag’s pore size is too large, it won’t capture all the contaminants, and if it’s too small, it can cause pressure drop and reduce flow rates.

Benefits of Using a Liquid Filter Bag

Using a liquid filter bag provides several benefits, including:

- Improved Liquid Quality: A liquid filter bag can effectively remove contaminants from liquids, improving the quality of the liquid and preventing damage to downstream equipment.

- Cost-Effective: Liquid filter bags are cost-effective and can be used multiple times before needing replacement.

- Easy to Install: Liquid filter bags are easy to install and require minimal maintenance.

- Environmentally Friendly: Liquid filter bags are made from synthetic materials, making them environmentally friendly and easy to dispose of.

- Versatile: Liquid filter bags are suitable for use in a wide range of applications, including water treatment, chemical processing, food and beverage processing, and more.

Choosing the Right Liquid Filter Bag

When selecting a liquid filter bag, it’s essential to consider several factors, including the pore size, material, and compatibility with the liquid to be filtered. A trusted supplier, such as FILWAVE, can help you select the right filter bag for your specific application and provide guidance on installation and maintenance.

Conclusion

In conclusion, liquid filter bags are a cost-effective and efficient solution for removing impurities from liquids in a range of industrial processes. By understanding how they work and the benefits they provide, you can make an informed decision when selecting a filter bag for your specific application. At FILWAVE, we are committed to providing high-quality filter bags and media, fast delivery, and exceptional customer service to help our clients improve their liquid filtration processes.